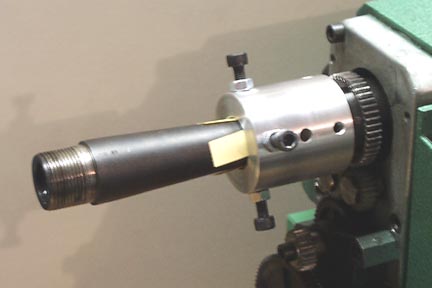

1. The rear spindle extension/spider. I had to use a square AL piece,

as round bar wasn't available. It replaces the rear nut on the

spindle. Thought I would have to make a spanner wrench to get the old

one off, but it was only finger tight. Bored and inside threaded to M27

x 1.5 and tapped 4 equidistant places each end. The end that's threaded

onto the spindle is locked in place with setscrews on top of #2 lead

shot to protecte threads and lock as in a lock ring on a reloading die.

The 4 holes at the back end are tapped to M6x1 to accept cap screws to

restrain and help center the work ( in this case, a Rem. 700 barrel).

The 2 holes amidships are for inserting a rod (phillips screwdriver) for

R&R. Pieces of paper are to protect barrel finish. File = Spider

|

2. Same setup (after the fact) at chuck end, showing the barrel muzzle

setup and threaded to accept a muzzle brake. Titled Businessend.

|

3. Showing the muzzle brake fitted on the barrel. Titled brake.

|

4. Showing my solution to the "clashing" problem with the gear lever in

neutral. It is a +/- 1/16" thick metal plate with detents drilled. It

is attached to the housing by tapping the housing to accept screws which

go through slotted holes in the plate. After adjusting the plate to the

proper position and tightening the screws, the clash in no longer a

problem. Titled FWD-REV.

|

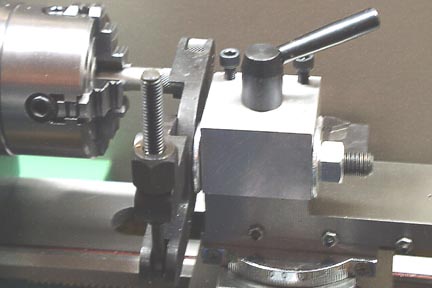

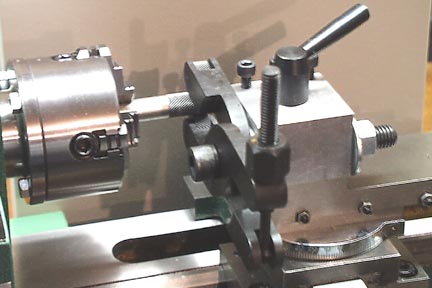

5. Two views of a commercial scissor knurling tool mounted via an

aluminum block at the toolpost. The cap screws are for a 3/8"

toolholder slot milled into the same block (point barely visible in one

view).

|

5. Two views of a commercial scissor knurling tool mounted via an

aluminum block at the toolpost. The cap screws are for a 3/8"

toolholder slot milled into the same block (point barely visible in one

view).

|

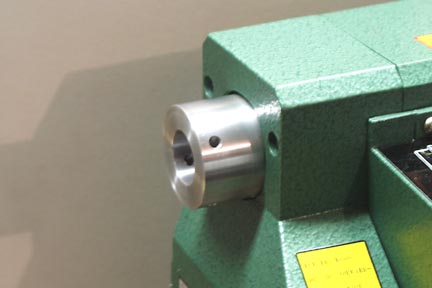

6. Finally, a view of the spider with the gear cover in place.

Included because the spider also serves to keep chips out of the gears

because they have to clear the cover before falling out. I opened the

cover to clear the spider. The spider without centering screws poses no

hazard because it's too smooth to grab a finger or clothing. Titled Tailcover.

|

|