| 04/20/2000 |

Recently I noticed that the lathe made a clunk, and then started slipping the drive belt. I looked at the motor & saw that the drive belt had broken some of the bands of fiberglass, reinforcing it. I got on the phone & ordered replacements from HF. They are on back order I was told. Back order for 7x10 parts means they will ship from the manufacturer in CHINA. I looked in the STOCK DRIVE PRODUCTS Metric catalog & found belts but I had a little dificulty since the belt was worni (making measuring more of a guess ) & I didn't want to guess at the size. I went to http://www.mcmaster.com and looked in their Power Transmission section & found they had metric belts but they were BIG. I kept looking & found the XL series belts were very close in size, but not quite the right size. Then it occured to me that if they carried the pulleys in XL size I could replace the whole works. So a little digging later I found that the had the XL Series pulleys but only in even number tooth varieties. The 7x10 has a 17 tooth pulley on the motor and a 31 tooth pulley on the spindle side. I found 16, 18, 30 and 32 tooth versions. So being in an adventurous mood, I ordered one of each. When they arrived I noticed right off that the 32 tooth pulley was too large to fit on the spindle drive shaft. if I could have gotten it on the shaft it would rub against the spindle itself. So that one was out. I bored out the holes on the 16, 18 & 30 tooth pulleys to give a snug fit, and then not having a keyway broach I decided to just drill a hole radialy & thread it 10-32, then put a 10-32x3/8" set screw in to lock the pulley to the keyway on the shaft. Supprisingly this worked very well. The one thing I noticed was that the 70 tooth XL belts I ordered ( the metric one was 70 teeth ) were too long for me to use the 16 tooth pulley. I just ordered an xl130 13" ( circumfrence ) 65 tooth belt. that should be short enough to use the 16 tooth pulley & slow the lathe down. Using the 18 tooth pulley causes the spindle to run faster ( a little ) than the 17 tooth original, not to mention that the spindle has a 30 tooth instead of a 31 tooth. The total effect is to raise the RPMs a little. Honestly I cannot see a difference by eye but logic tells me its faster. Here is the list of parts & their #'s:

The pulleys had mounting collars on them which I removed with the mill, and the 30 tooth pulley had pressed on flanges which I pulled off & then milled the raised area away to bring the pulley down to the same thickness as the stock metric pulley. This worked out really well & all I had to do has drill & tap the set screw hole between a couple teeth, and use the original spring clip to mount it. Mounting the 18 tooth was just as easy, except that it did not have flangeson it. I mounted it so that the mounting collar is away from the motor to line up the pulleys so that the belt would run true. Next came adjusting the motor to take up the slack in the belt. The last few images below sow the motor positioning setscrews & the motor holding nuts. I adjusted the motor sothat there was about 1/4" of play in the belt. This is about perfect, because when you tighten the motor hold nuts it takes the last bit of looseness out of the belt without putting too much tension against either pulley. When the motor runs there is no bogging dowh of the motor, and also no tooth grinding noise when the belt is loose. I am quite pleased with this modification as now I can get replacement belts from McMaster Carr in 48 hrs if I have a problem.

|

|||||||||||||

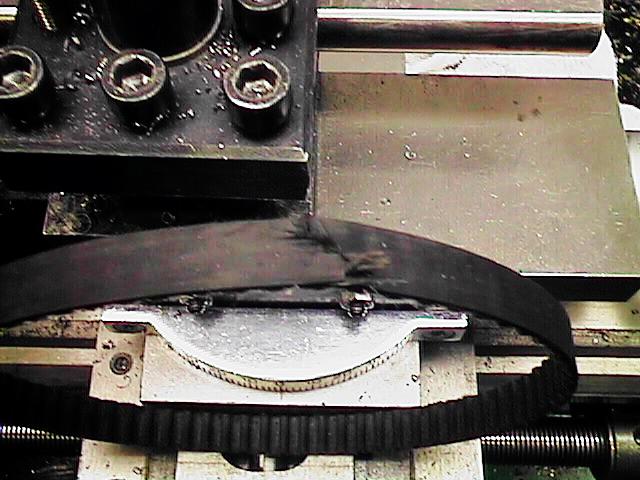

Broken Metric Timing Belt |

Another view of the broken Timing Belt |

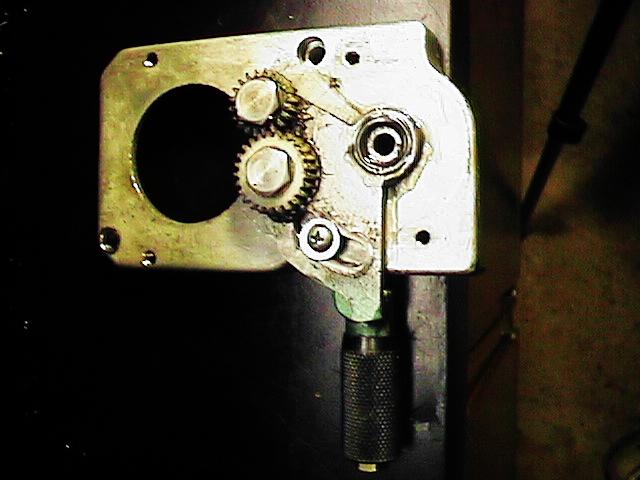

FNR Housiong, w/A pos gear housing removed. |

||||||||||||

A position gear housing. keep well lubricated. |

Step 1. Remove the F-N-R Housing |

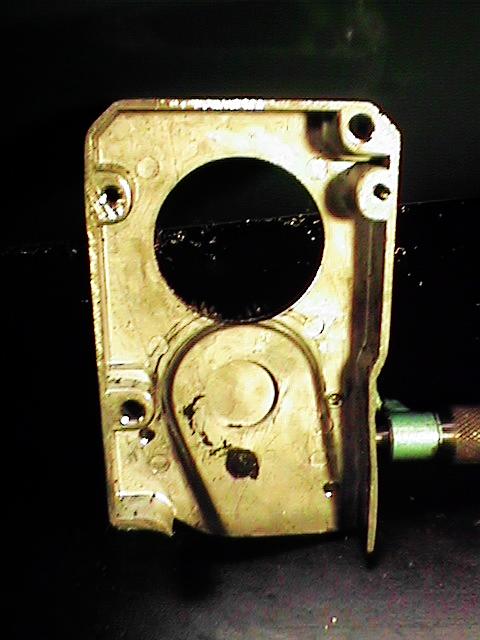

FNR housing rear view. Notice wear marks from belt rubbing. |

||||||||||||

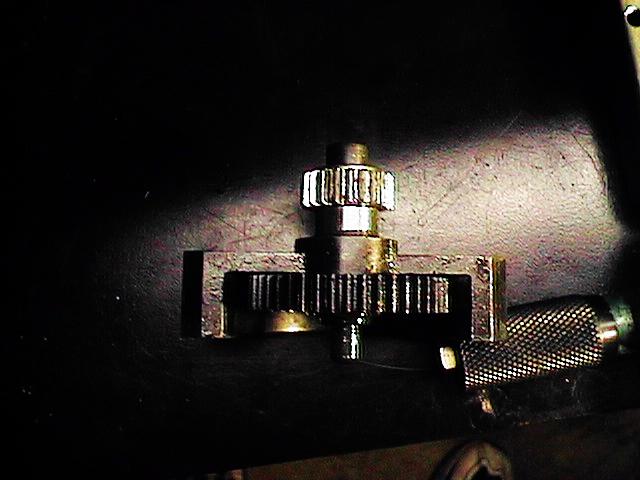

FNR detents drilled w/#1 center drill for more positive lock in position. |

FNR Housing gone. Broken belt removed. |

Another view of Metric Belt & metric gears. |

||||||||||||

Metric Spindle drive gear. |

Std. XL Series Gear. I had to mill the hub off with the Mill. |

XL Series Belt Conversion done. Now to adjust the Belt Tension. |

||||||||||||

Metric Spindle drive gear. |

Motor controller removed to show motor adjustment nuts & studs. |

Motor downward adjustment. |

||||||||||||

Motor upward adjustment. |

Tighten these to lock motor in position. |

Motor Label. 3/4hp? Maybe just before it burns up!. |

||||||||||||

This page last updated 04/20/2000

You are Visitor number since 06/23/1999

|

|

For more information email me at: pth3k@virginia.edu

All above images Copyright (c)1999

Ty Hoeffer