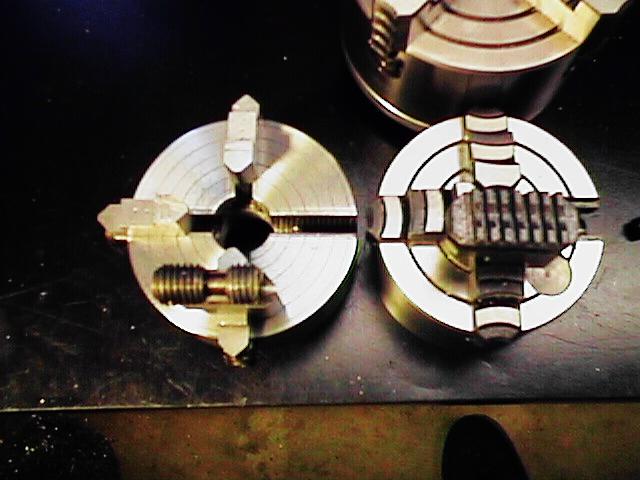

Fig. 1

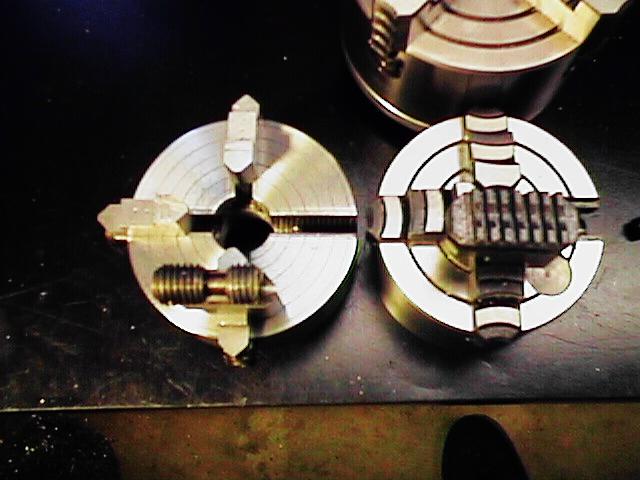

The TAIG, ABS, and J&L 3" 4-Jaw Chucks

|

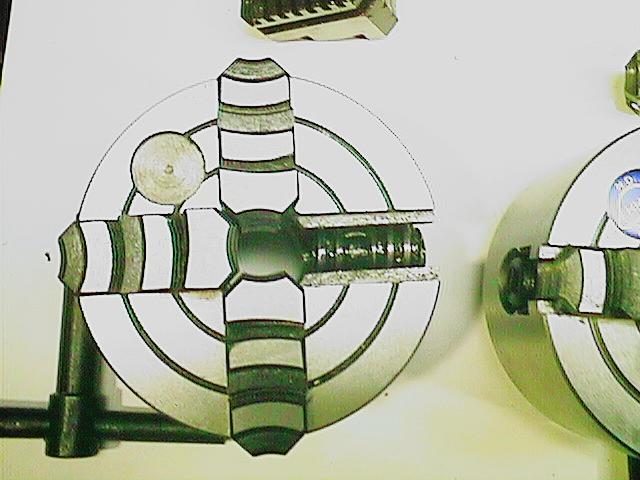

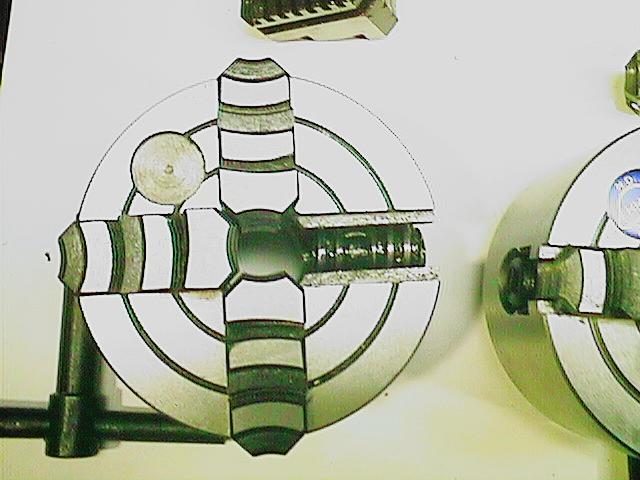

Fig. 2

Taig and ABS 4 jaw chucks

|

Fig. 3

Taig and ABS Bottom View

|

Fig. 4

The TAIG and ABS Bottom View 2

|

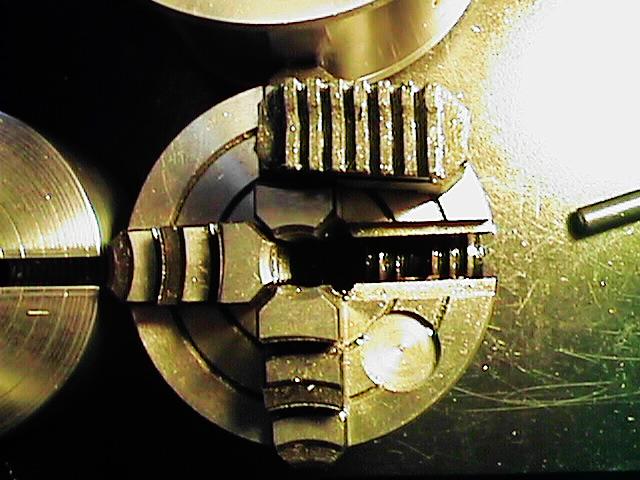

Fig. 5

Taig and ABS Jaw Threads

|

Fig. 6

ABS Jaw Adjustment Threads

|

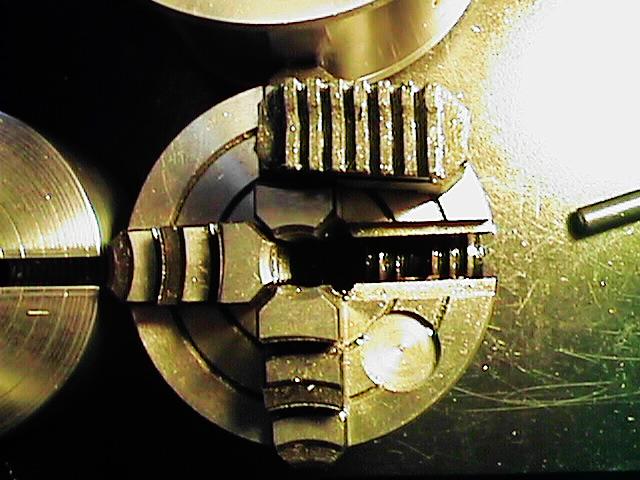

Fig. 7

ABS Jaw Teeth. Very Coarse & Rough

|

Fig. 8

ABS & J&L 3in 4-Jaw

|

Fig. 9

ABS & J&L Side View

|

Fig. 10

ABS & J&L Jaw Teeth

|

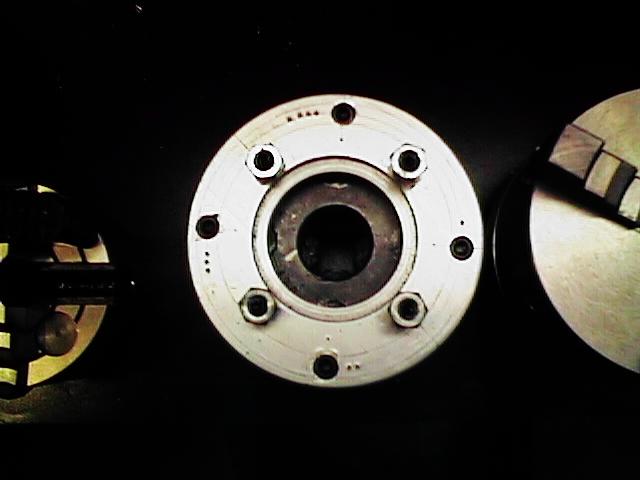

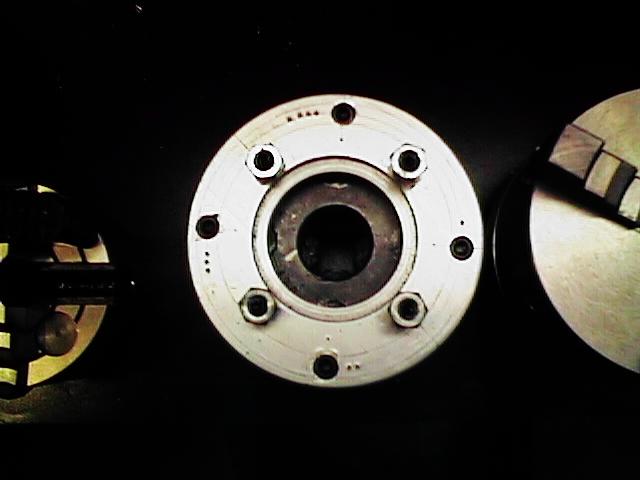

Fig. 11

Mount for 4" ABS 4-Jaw

|

Fig. 12

Side View of ABS 4" 4-Jaw

|

Fig. 13

Side View of J&L 4" 3-Jaw

|

Fig. 14

Front View of J&L 3-Jaw

|

Fig. 15

HF 7x10 3" 3-Jaw Logo

|

Fig. 16

J&L 3" 4-Jaw Logo

|

Fig. 17

J&L 4" 3-Jaw Logo

|

Fig. 18

|

|

When I first bought my 7x10 I felt I needed a 4-Jaw chuck. So I looked & found Jose's reference to the Taig 4-Jaw. The price was right (~$54.00) so I ordered one. It can be seen in Fig. 1, Fig. 2, Fig. 3, Fig. 4 & Fig. 5. This chuck is an exceptional value, and is very easy to mount. All it needs it to be mounted face to face with another chuck. Either in a 4" 3 or 4-Jaw or on a shaft with the stock 3-Jaw. I prefer to mount chucks in a 4-jaw as you can get it to run true easier. It is important to mount a chuck with as little runout as possible. Excessive ( or any for that matter ) runout will induce error in the items turned in that chuck. Once mounted you machine out an area to mate with the spindle. If you have made a spindle template you can use that to mark the locations of the mounting holes. I find that this chuck is EASY to get things centered with as the adjusting screws are a fairly fine thread. You may notice I faces off the chuck & re-grooved the face with 1/4" grooves to help centering.

|

|

Next I found some ABS chucks on EBay for about $40 for a 3" and $50 for a 4" 4-Jaw chuck. I could not resist the low price, so I bid on them & won. Upon arrival, the chucks appeared to be well made but I noticed that the adjusting screws were VERY coarse ( See Fig. 1 - Fig. 10 ). I have made items with the 4" 4-jaw but have had to spend a great deal of time tinkering with the adjustment screws to get the workpiece to run with ~.001" of runout, let alone <.001". The Taig above ( Fig. 2 ) is a breese to adjust things to <.001" of runout. Other than that the chuck as hardened jaws, is solid, and comes with a T handle wrench.

|

|

J&L placed their 4" 3-Jaw chucks on sale for around $37. This was too good a thing to pass up. I didn't have a 4" 3-jaw chuck so I called them up and ordered the chuck. It arrived in less than a weeks time. I was supprised to find the same logo on it as the stock 3" 3-Jaw chuck that came with the 7x10. I could not have been happier. The plain back already had a recess in it that was larger than the 7x10's spindle so I ordered a couple 4"x1" Aluminum discs from Metal Mart to use as mounting adapters. The finished product can be seen in Fig. 11 - Fig. 14, also the bottom looks exactly like Fig. 11. I was lazy & did not make the adapter thinner. It is about 3/4" thick and could probably b as thin as 1/2" or even thinner if you use c-sunk flat head screws. I find this chuck to be excelent in workmanship, and is quite accurate ( <.003"MAX acording to the test sheet provided by Manufacturer.) though mine seems to have about .0015 - .002" runout both at 1/4" and 3".

|

|

Finally I had heard everyone else talking about the J&L 3in 4-Jaw. I figured all my other 3" 4-Jaw chucks could use a new sibling. So I got online pointed Netscape at http://www.jlkdirect.com/Order/default.asp. and ordered Part Numer PCC-19500A. It lists for $68.00 but it was on sale for $60.00 through March 2000. It arrived TWO days later. I didn't even have to request UPS-BLUE. It is a NICE chuck. the jaws move smoothly and it is easy to adjust. I chucked my 5C collet chuck to clean up some threads and had no trouble getting it down to about 1/4 of a thousandth of an inch. YES ~.00025". The DTI needle just barely wiggled on my .0005" DTI. Good enough in my book. See Fig. 1, Fig. 8 - Fig. 10. All I had to do to this chuck to mount it was deepen the threaded holes on the back so I would not have to shorten the 6x35mm studs I already had on hand, screw in the studs, wiggle the chuck on the spindle flange, and tighten the nuts. If you look at the pictures above, the Stock 3" 3-Jaw, the J&L 3" 4-Jaw, and the J&L 4" 3-Jaw all have the SAME LOGO on them. See Fig. 15, Fig. 16 & Fig. 17. That made me feel better.

|